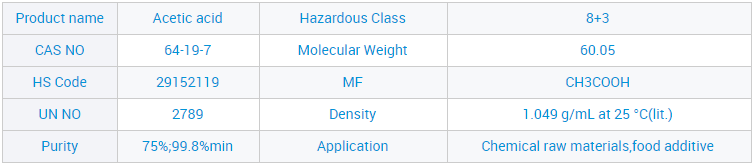

Gaa CAS 64-19-7 Ледена сирћетна киселина

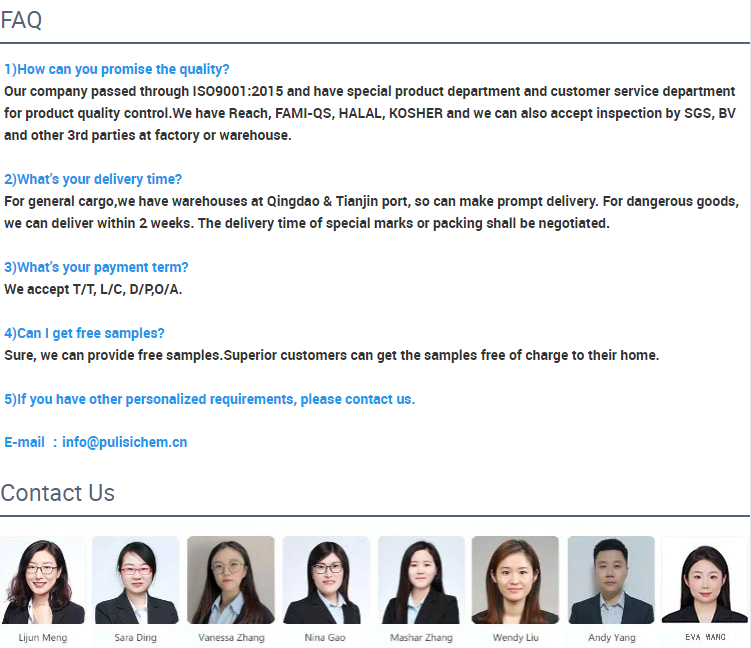

Са добрим кредитним резултатом за мала предузећа, изванредним постпродајним услугама и модерним производним погонима, стекли смо фантастичну репутацију међу нашим купцима широм света за Gaa CAS 64-19-7 ледену сирћетну киселину, прецизне процесне уређаје, напредну опрему за бризгање, линију за монтажу опреме, лабораторије и раст софтвера су наше одлике.

Са добрим кредитним резултатом за мала предузећа, изванредним постпродајним услугама и модерним производним погонима, стекли смо фантастичну репутацију међу нашим купцима широм света. Усвојили смо технику и систем управљања квалитетом, заснован на „оријентисаности на купца, репутацији на првом месту, обостраној користи, развоју заједничким напорима“, поздрављамо пријатеље из целог света на комуникацију и сарадњу.

Године 1847, немачки хемичар Херман Колбе је постигао прву синтетичку производњу глацијалне сирћетне киселине Gaa из неорганских материјала. Процес је укључивао хлорисање угљен-дисулфида да би се формирао угљен-тетрахлорид, након чега је следила пиролиза, хидролиза и хлорисање да би се произвела трихлорсирћетна киселина, која је затим електролитички редукована до сирћетне киселине.

Године 1847, немачки хемичар Херман Колбе је постигао прву синтетичку производњу глацијалне сирћетне киселине Gaa из неорганских материјала. Процес је укључивао хлорисање угљен-дисулфида да би се формирао угљен-тетрахлорид, након чега је следила пиролиза, хидролиза и хлорисање да би се произвела трихлорсирћетна киселина, која је затим електролитички редукована до сирћетне киселине.

До 1910. године, већина глацијалне сирћетне киселине (GAA) добијана је сувом дестилацијом дрвног катрана. Процес је укључивао третирање катрана калцијум хидроксидом да би се формирао калцијум ацетат, који је затим закисељен сумпорном киселином да би се добила сирћетна киселина. У то време, Немачка је производила око 10.000 тона глацијалне сирћетне киселине годишње, од чега се око 30% користило у производњи индиго боје.